- INTERTECH TECHNOLOGIES PVT. LTD.

Engineers to Healthcare Industry®

Rotary bottle washing machine

|

INTRODUCTION:

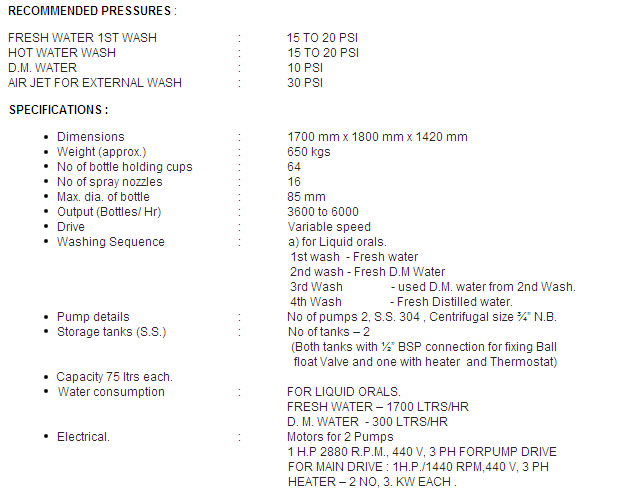

Rotary Bottle Washing Machine is designed to wash various types of bottles made of glass, plastics or other material. It can also be used for cleaning used bottles. The bottle washing is done through the 16 powerful stationary jet, which are located in washing zones. 2 no. tanks are mounted on separate stands. Out of 2 tanks one is provided with heater which is used as hot detergent tank. Outside washing is done by spraying the water throughout the S.S. shower on the inverted bottles. The machine works on Rotary principle with Geneva mechanism and needs manual loading and unloading of bottles.

WORKING PRINCIPLE:

The machine operates on the rotary principle with “GENEVA MACHANISM” . The inverted bottles are loaded into the cups fitted on rotating platform. Stationery jets 16 nos. are centred below the cups for different washes at 4 stations. One station is provided for outer wash by showering water. Solenoid valves are provided to enable the regulations of timing and sequence of the various washing media as per specific requirements. The pressure of the jets as adjusted with the help of control valves in each line. The pressure gauge indicates the line pressure at which the machine has been set. The very speed drive pulley is provided for different output between 60 to 100 bottles per minute. As the rotating carbon plate is eliminated in new design, The leakage is avoided there by minimizing the maintenance.

OPERATION

- Clean he tanks thoroughly with detergents and fresh water to remove any trace of dirt etc.

- Fill the detergent tank with water and detergent in the ratio of 10:1 or 15:1 (or as required) and mix thoroughly. A Stainless steel mesh filter is provided at the detergent outlet, which required occasional cleaning.

- The fresh water tank is to be connected with an overhead tank which is to be arranged by customer.

- Make suitable connections for D.M. Water.

- Ensure that the S.S pipe line holding the jets is properly cleaned before loading the bottles.

- Turn the pump switch and adjust the pump pressure of each pump (or wash) with the help of control valve.

- For normal operations, two operators are needed.

- Run the machine now. The washing process is completely automatic. The first operator merely places the inverted bottles to be washed on empty cups and the second operator removes one that has been washe

|

|

|